Nisal Ovitigala

Mechanical Engineer

About Me

- Full Name:Nisal Ovitigala

- School:Massachusetts Institute of Technology

- Graduation Year:2021

- Residence:Boston, MA

- Hometown:Sri Lanka

Hello There!

I’m an international student in MIT's class of 2021 pursuing a Bachelors in Mechanical Engineering. I am comfortable with a variety of mechanical engineering tools such as 3D printing, manual and CNC machining, injection molding and thermoforming. I also have experience with a variety of software tools such as Python, MATLAB, C/C++, Fusion 360, Autodesk CFD, Autodesk MoldFlow and Siemens Tecnomatix. Outside of class, I have been a part of a variety of research groups in the areas of robotics, nanoengineering, metallurgy and business. I've also been a lab assistant for an electromechanical systems class for nearly two years.

I am a hobbyist who likes to take apart and tinker with everyday items before improving and rebuilding them. During my free time, I enjoy riding my homemade electric motorcycle around Boston, flying FPV drones and exploring patches of nature wherever they may exist.

My Resume

Download my resume here

-

Work Experience

-

Haptic Feedback System Developer

MIT Micro/Nano Lab (September 2020 - Present)- Developing a 1DOF haptic feedback controller to interface with an Atomic Force Microscope to allows users to feel attractive and repulsive force that occur on the nano scale.

- Conducted extensive literature review on haptics, learning and human design to optimize feedback controller design

- Corresponding with AFM manufacturer to modify microscope software to accept analog signals for control and output feedback signals

-

Automation System Developer

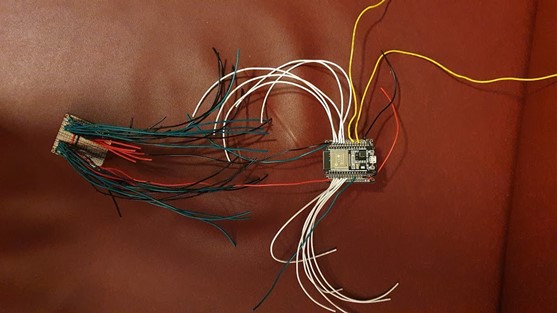

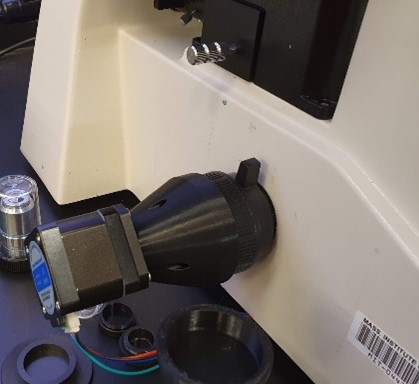

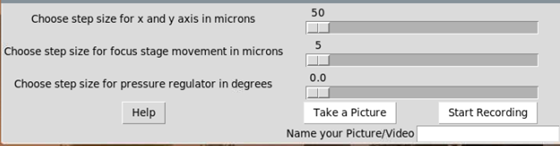

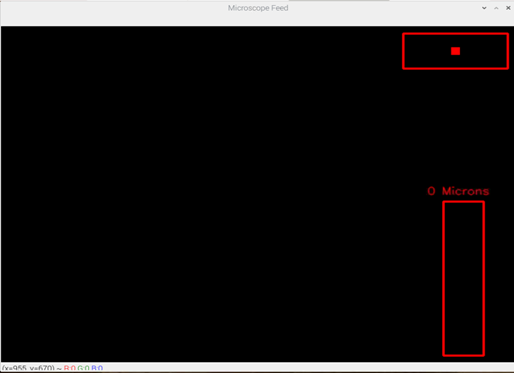

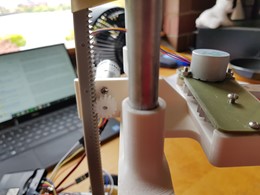

MIT Micro/Nano Lab (June 2020 - September 2020)- Enhanced remote learning during pandemic for over 50 students by modifying a compound light microscope to controlled and viewable through the internet

- Increased motion precision by three orders of magnitude to achieve micrometer-level precision which allows users to conduct Z-height scans without additional hardware

- Improved user experience by implementing photo/video recording features and a GUI for a live coordinate readout

-

Robotic Systems Researcher

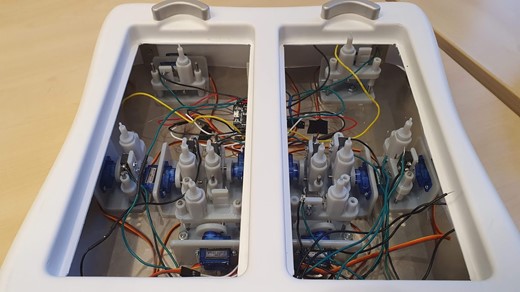

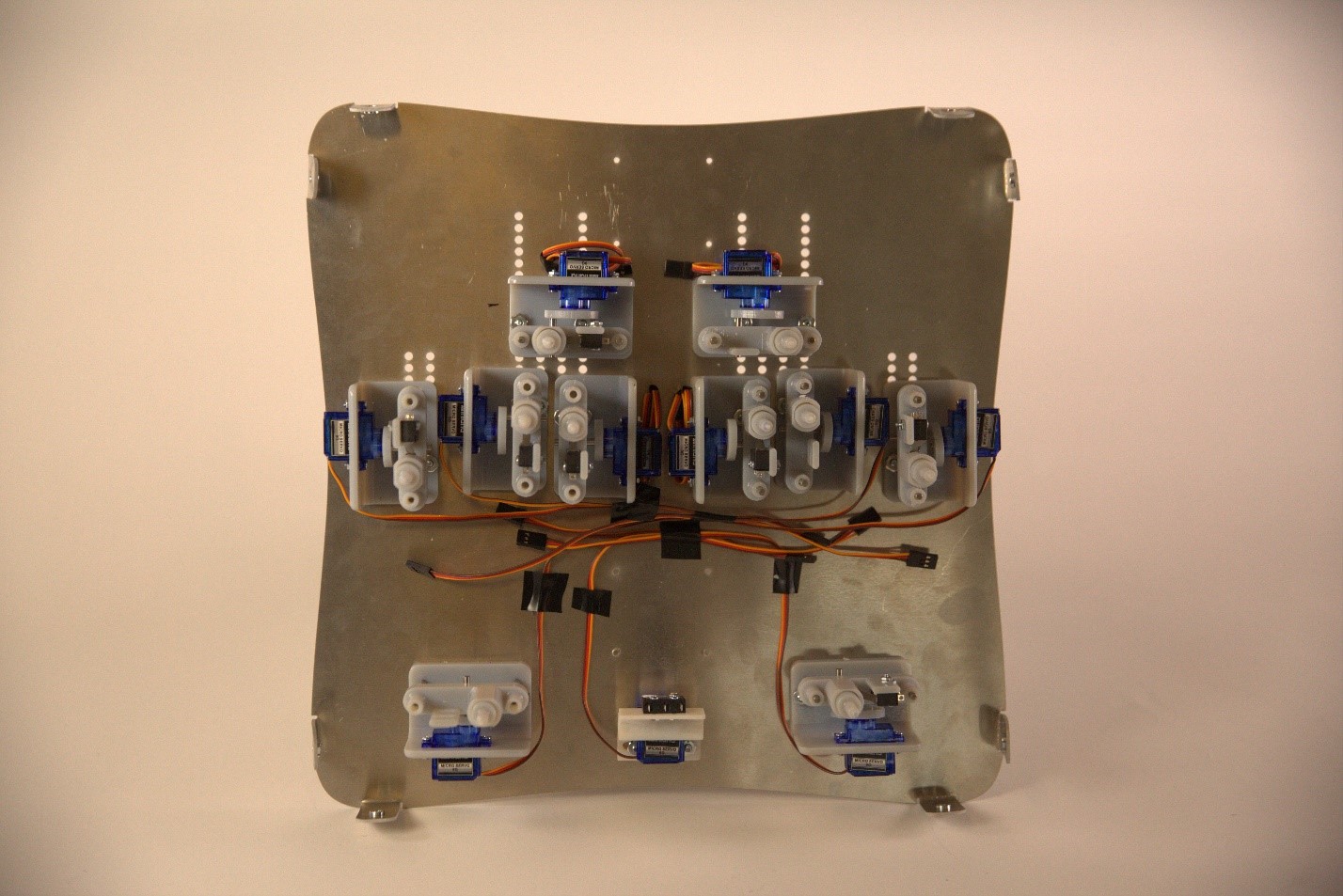

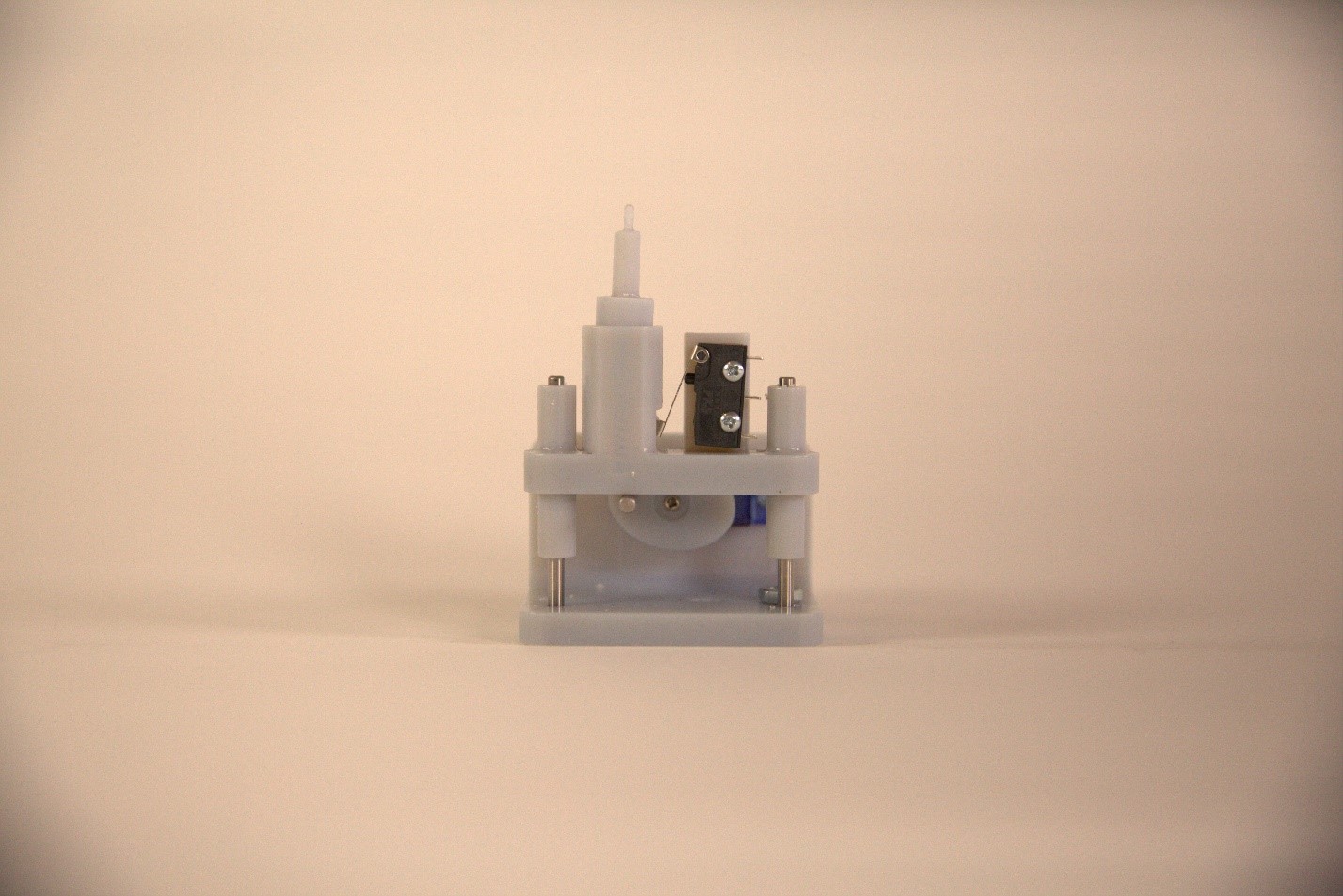

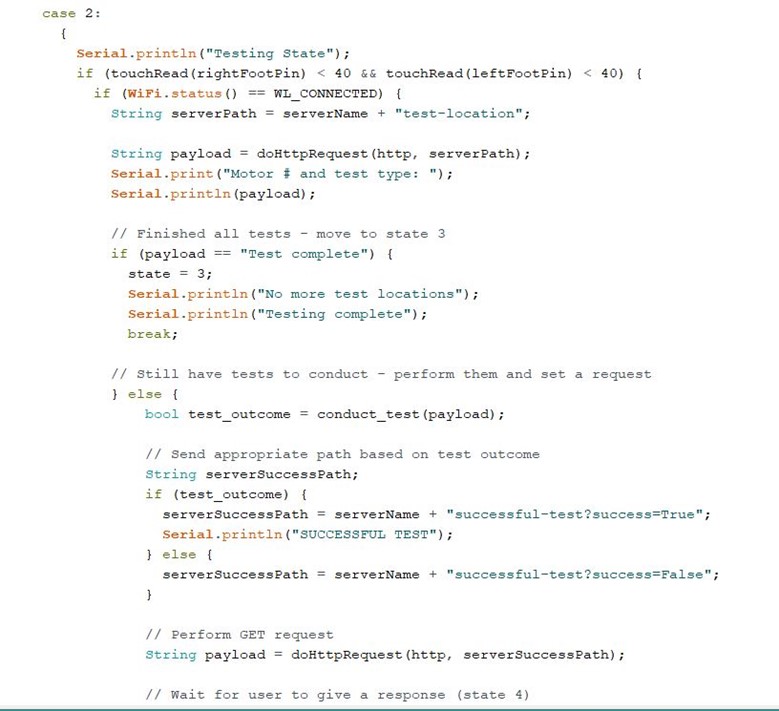

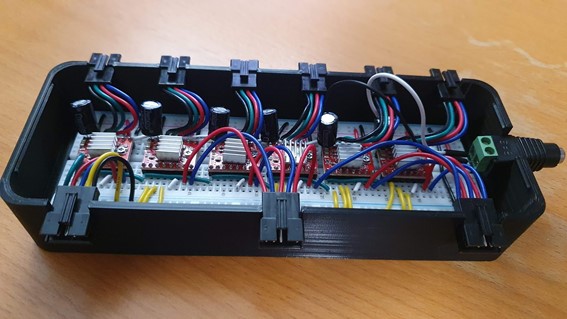

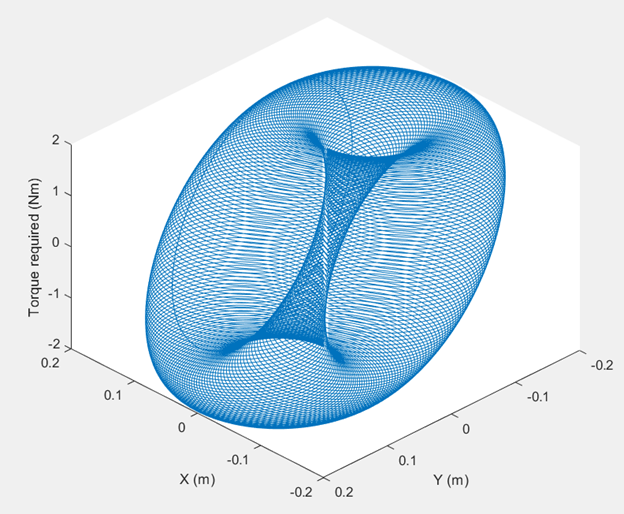

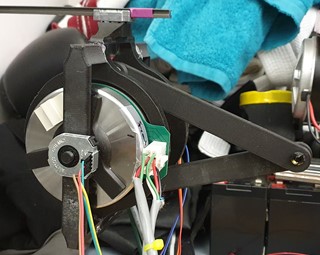

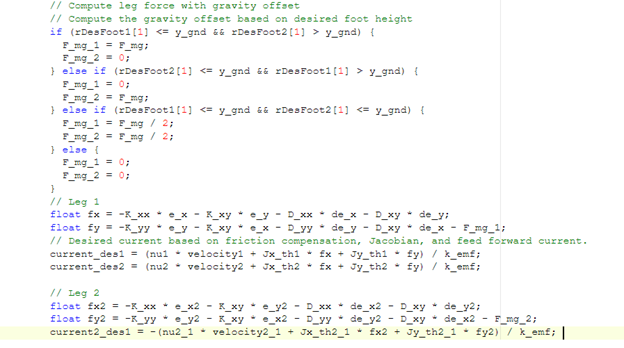

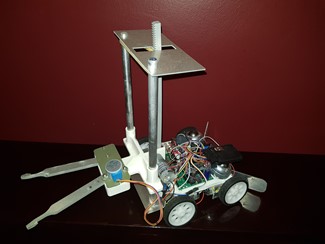

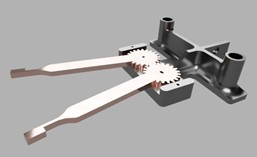

MIT d'Arbeloff Lab (January 2020 - March 2020)- Developed small, 3D printed robotic legs to test novel control algorithms for viability before scaling it up to full-sized robotic legs.

- Cut down prototype time by 30% by providing MATLAB script that visualizes robotic limb workspace and torque requirements for a given leg geometry

- Developed a hybrid force/position control walking algorithm by interfacing MATLAB code that defines Bezier trajectories and control parameters with C++ code that runs a control loop

-

Mechanical Engineer

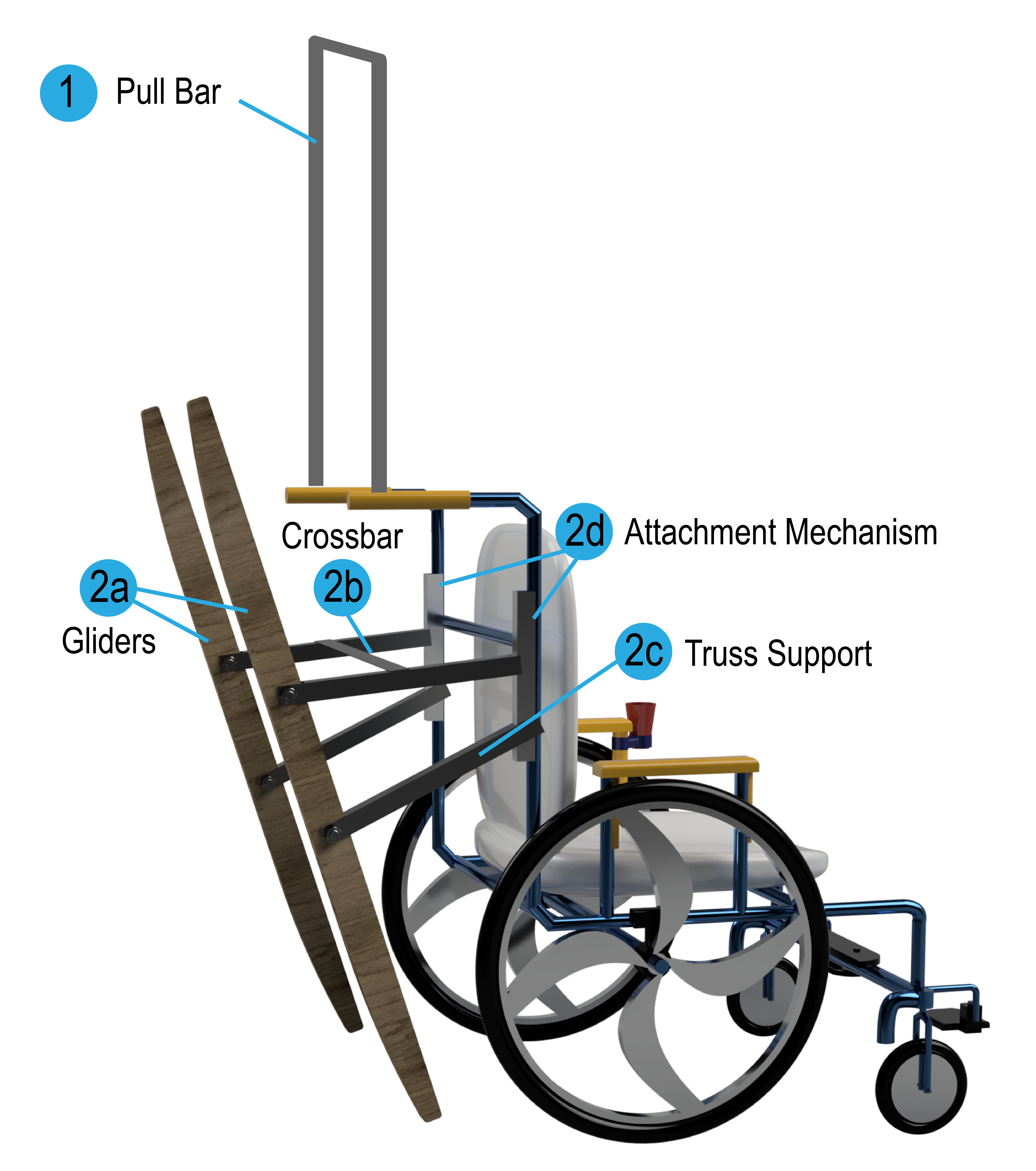

TILT (January 2020 - Present)- Designed a low-cost modular wheelchair attachment that allow users to traverse staircases

- Analyzed data to improve design criteria from alpha prototype user tests conducted with over 20 wheelchair users in India

- Iterated design using DFM and DFA criteria to decrease manufacturing stock waste and reduce assembly time from two hours to twenty minutes

-

Innovation and Performance Intern

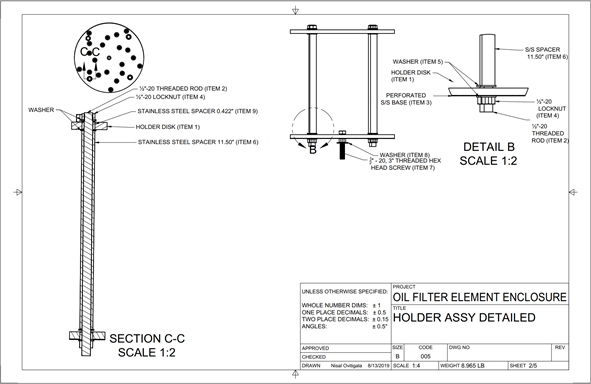

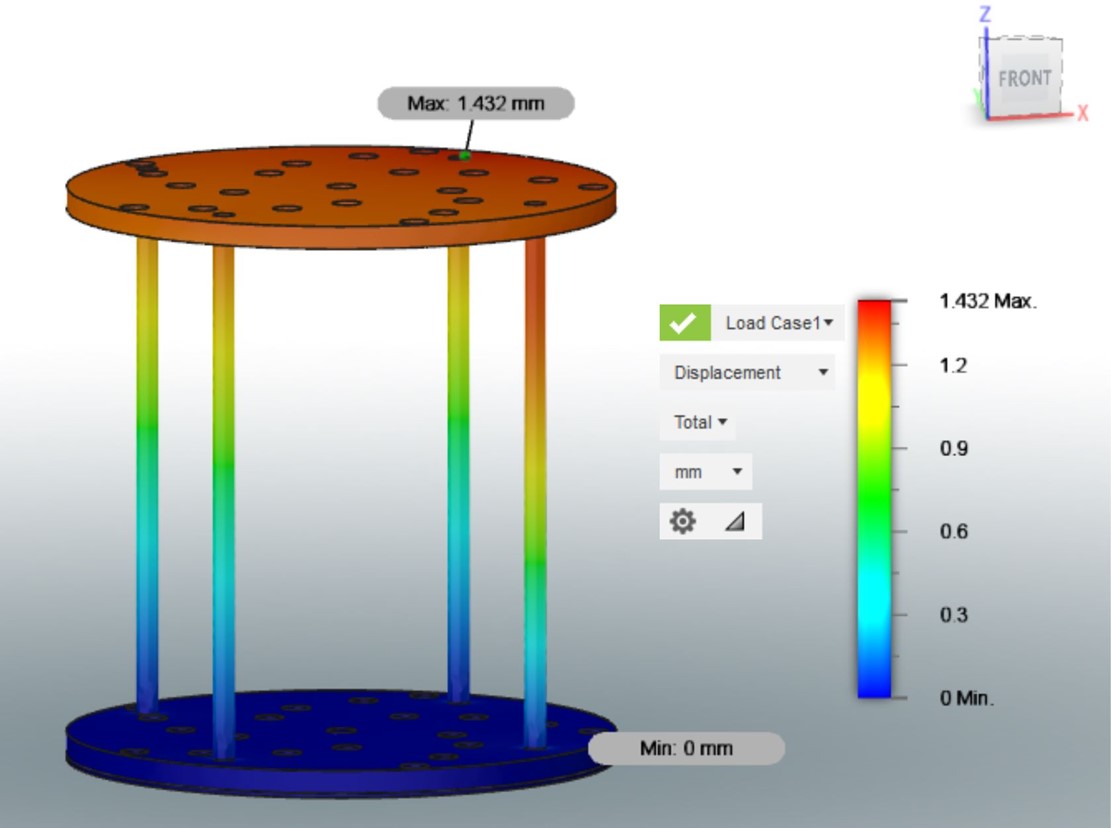

Keolis Commuter Services (June 2019 - September 2019)- Coordinated and led an interdisciplinary team to conduct locomotive engine testing

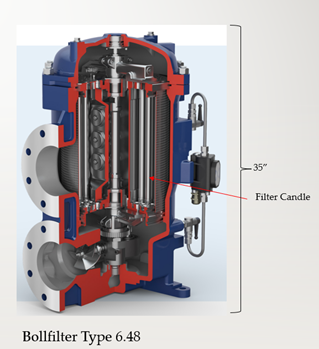

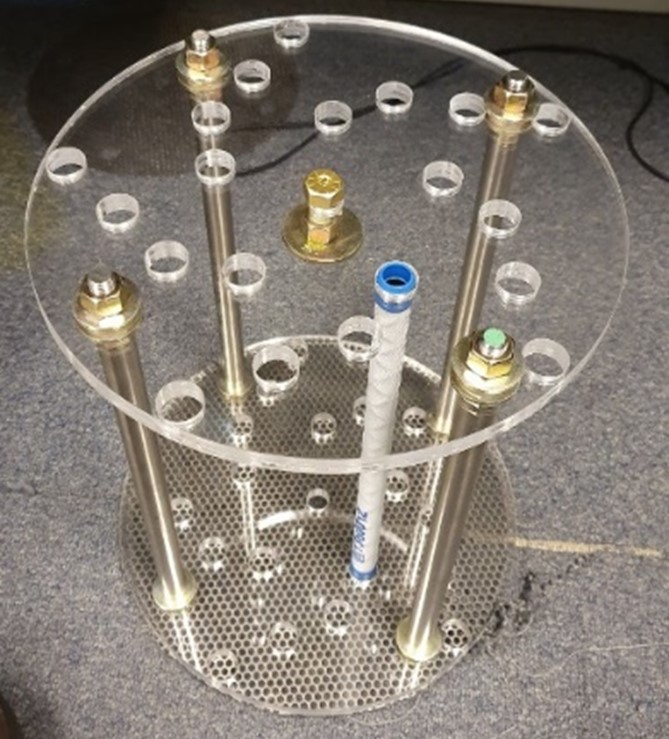

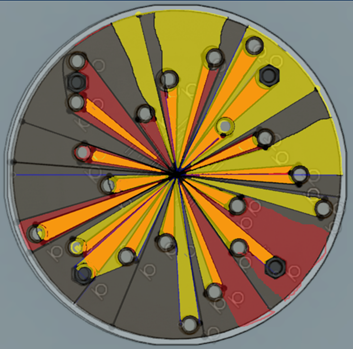

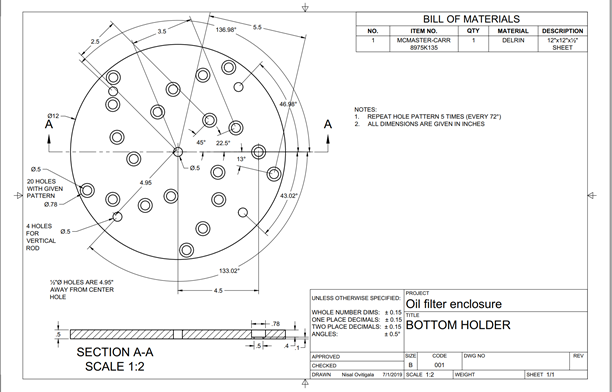

- Reduced maintenance time by 15% by resolving pump malfunction through root cause failure analysis

- Saved over $30,000 annually by integrating an oil filter cleaning system into maintenance schedule

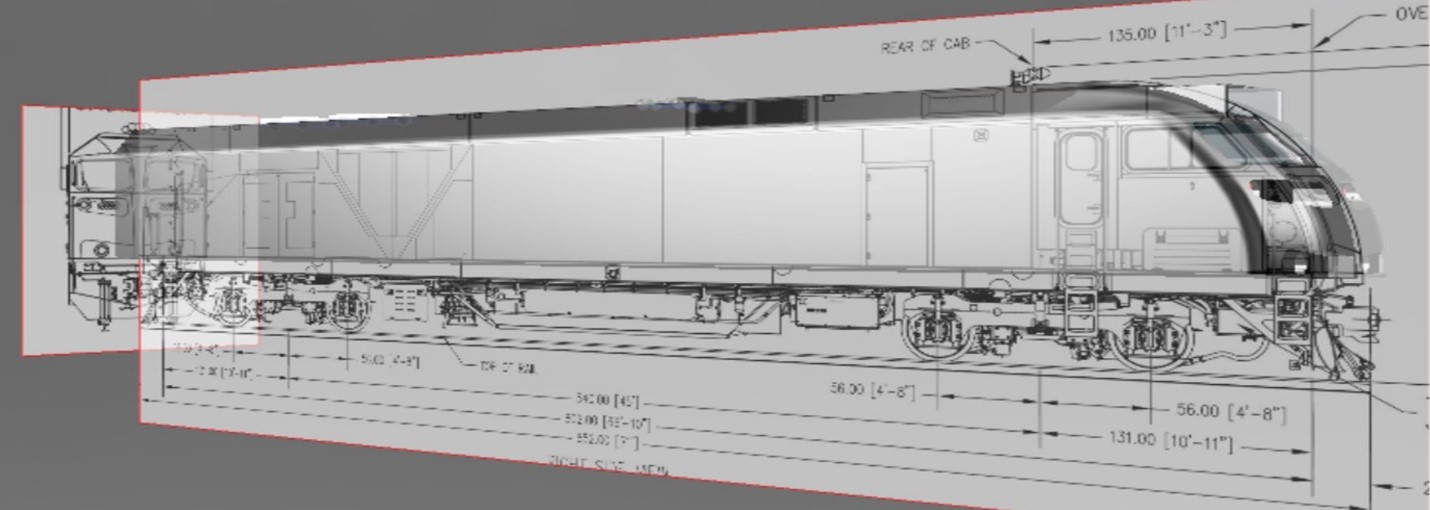

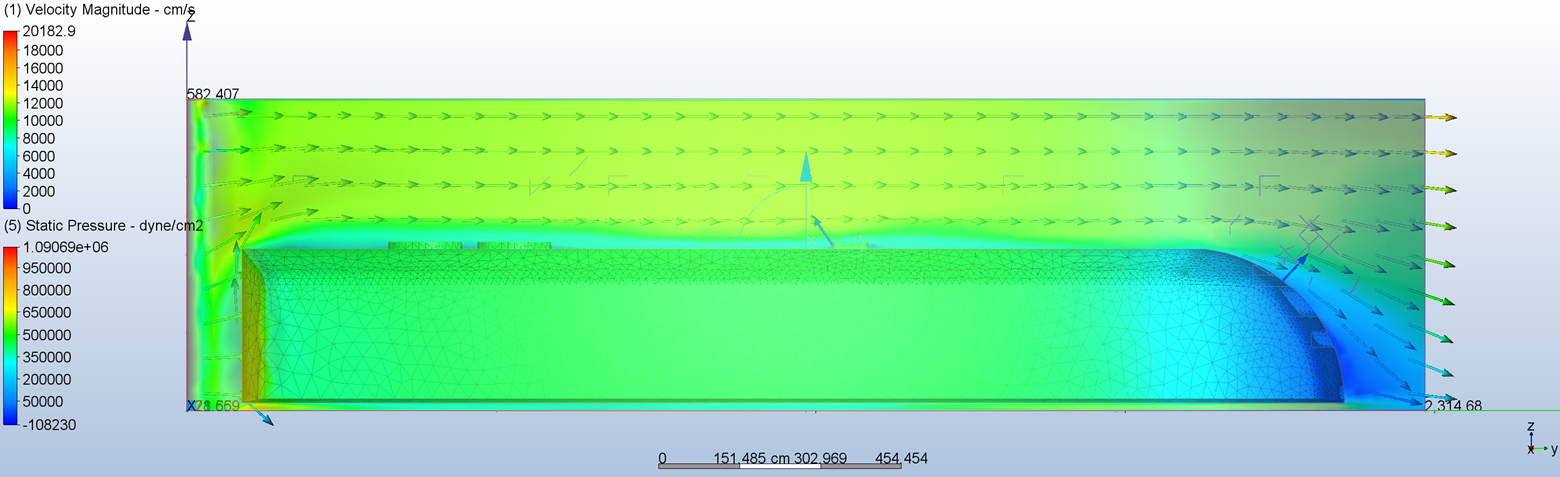

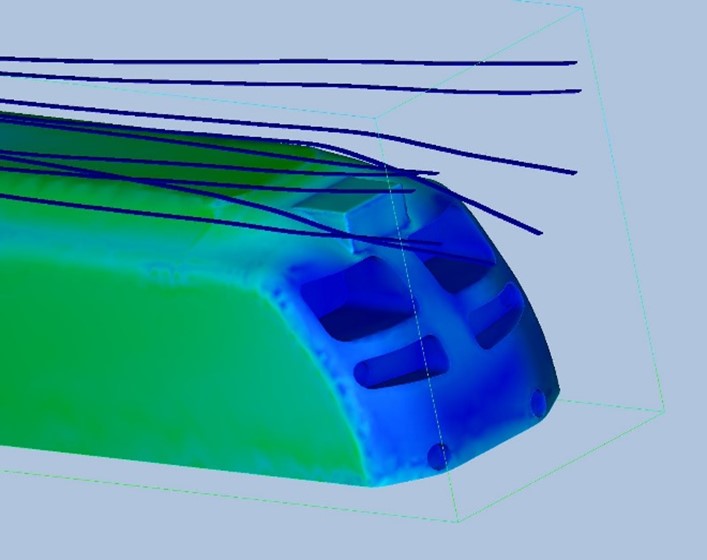

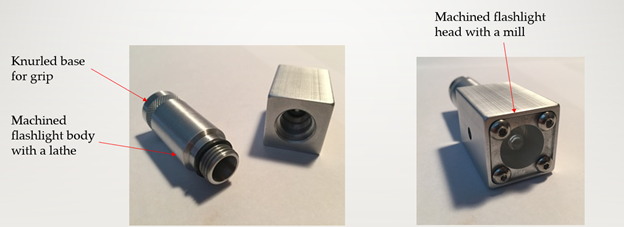

- Reduced headlight redesign project timeline by 6 months from data obtained through CFD simulations

- Designed 3D models of locomotives from engineering drawings for future modifications and simulations

-

Education

-

Massachusetts Institute of Technology

Bachelors Degree - 2017 - 2021Major: Mechanical Engineering

Focus: Electromechanical, Robotic and Control Systems

Concentration: Music Technology

Relevant Coursework: Mechanics and Materials, Dynamics and Controls, Thermal-Fluids Engineering Robotic Systems, Bio-Inspired Robotics, Numerical Computation for Mechanical Engineers, Instrument and Measurement, Design and Manufacturing, Product Design, Mechanical Engineering Tools, Fundamentals of Programming, Signals and Systems, Electronics for Mechanical Engineers

-

Gateway College Sri Lanka

High School - 2013 - 2017Focus: Science and Technology

Role: Deputy Head Prefect

Awards and Clubs: Monash University Future Leader Award, Fulbright Scholar Program, Head of Community Service Club, Edexcel High Achiever Award, SLMUN 2014 Organizer

Projects

Extracurriculars

Activities I do outside of academic work